Does frosted glass also have a process distinction?

Frosted glass is a glass that has been rendered opaque through a process that roughens or obscures the clear surface of the glass Due to the rough surface of the frosted glass, the light is diffusely reflected, and the light is transparent without perspective. It can make the indoor light soft and not dazzling. It is often used for window glass in places such as bathrooms that need to be concealed and can also be used for glass ceilings, which have dual functions of privacy and decoration.

The production methods of frosted glass include mechanical sandblasting, manual grinding or hydrofluoric acid dissolution. The common frosted glass process, frosting, and sandblasting, is to blur the surface of the glass so that the light can be scattered evenly after passing through the lampshade. It is difficult for ordinary users to distinguish these two production processes, which can be identified by the following methods.

frosted process: Frosting refers to soaking the glass in the prepared acidic liquid (or coating acid-containing paste), corroding the glass surface with strong acid, and at the same time, the ammonia hydrogen fluoride in the strong acid solution causes the glass surface to form crystals. Therefore, if the frosting process is done well, the surface of the frosted glass is extremely smooth, and the scattering of crystals produces a hazy effect. If the surface is relatively rough, the acid has serious erosion on the glass, which is a manifestation of the immature craftsmanship of the frosting master. Or some parts still have no crystals (commonly known as not ground to sand, or the glass has mottled), which also belongs to the master’s poor control of the craftsmanship. This process is technically difficult. The best feature of the process is the appearance of sparkling crystals on the glass surface, which are formed under critical conditions, mainly because the ammonium bifluoride has reached the point where it is running out.

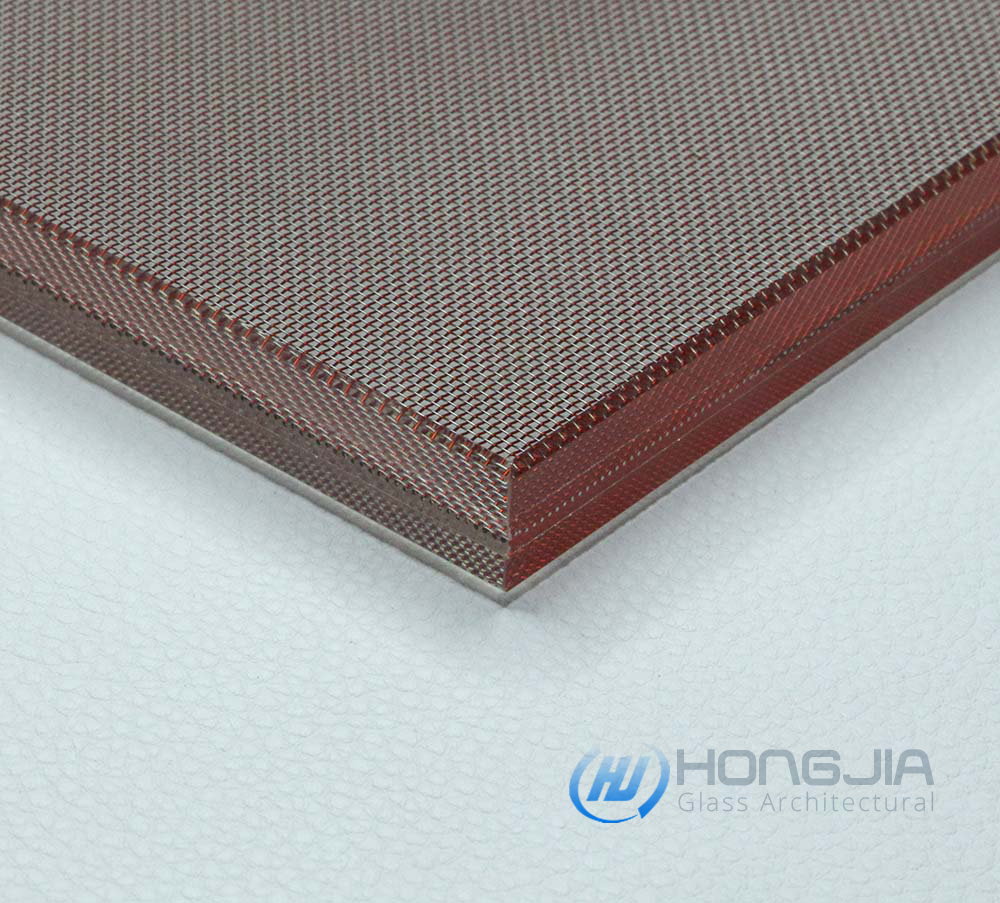

Sandblasting process: This process is very common. It hits the surface of the glass with the sand particles shot at high speed by the spray gun, so that the glass forms a fine concave and convex surface, so as to achieve the effect of scattering light, making the light appear hazy when passing through. The surface of sandblasted glass products is relatively rough. Because the glass surface is broken, it looks like white glass in the original clear glass. This method is moderately difficult to manufacture

Actually, the two processes are completely different processes. Frosted glass is more expensive than sandblasted glass, and the effect mainly depends on user needs. Some special glass is also not suitable for frosted. From the point of the pursuit of nobility, frosted should be used. The sandblasting process can be completed in general factories, but it is not easy to do the sandblasting process well.

If you have any ideas, please feel free to contact us anytime.

+86 0755 86152161 inquiry@hongjiaglass.com