Do you know electric engraved glass? Processing and application of electric engraved glass

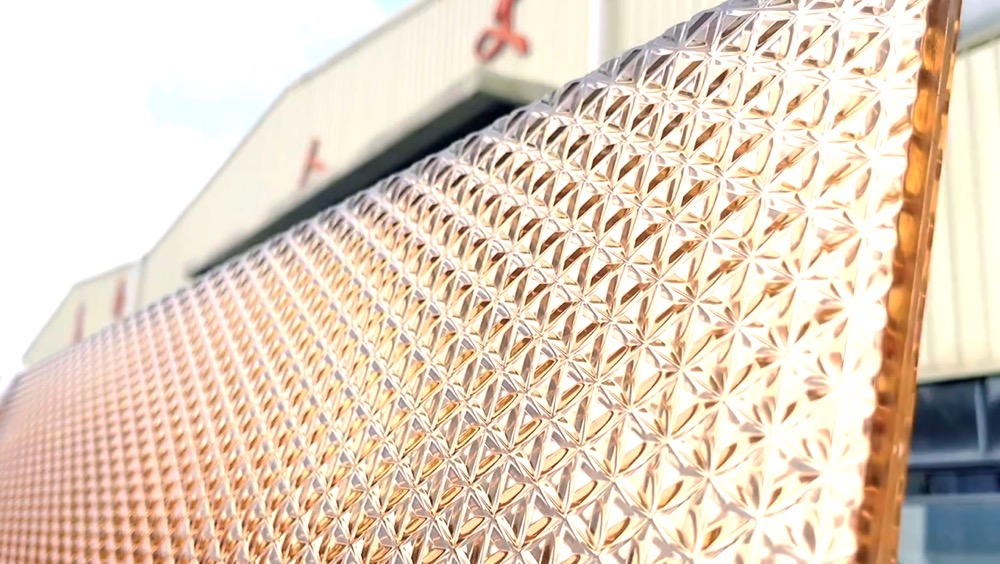

Electric engraving glass is to engrave and polish the glass through electric engraving tools so that the glass surface produces crystal clear three-dimensional lines, translucent decorative flat glass. Its unique decorative performance can not only fully light and transmit light, but also effectively limit and prevent clear perspective, with good aesthetic and concealment effects.

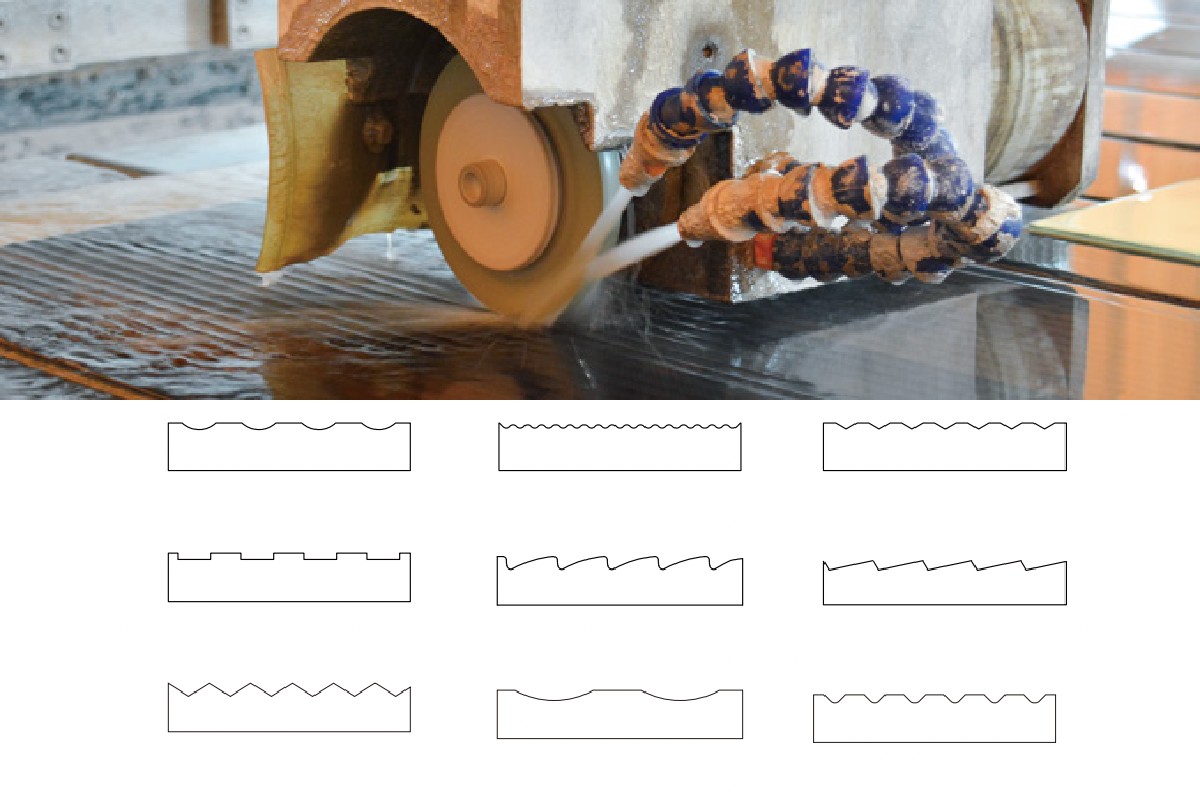

Electro-engraved glass is a CNC lathe using different shapes of abrasive tools. The travel of the X, Y, and Z axes is controlled by a computer program to engrave and polish the glass surface vertically and horizontally, so as to make the glass surface transparent, translucent, and crystal clear. three-dimensional lines. Its unique decorative performance can not only fully light and transmit light, but also effectively limit and prevent clear perspective, with good aesthetic and concealment effects.

It can electrocute complex patterns of straight lines, oblique lines, S-shapes, U-shapes, V-shapes, M-shapes, round lines, concave hemispheres, etc.

Smooth and jade-like texture

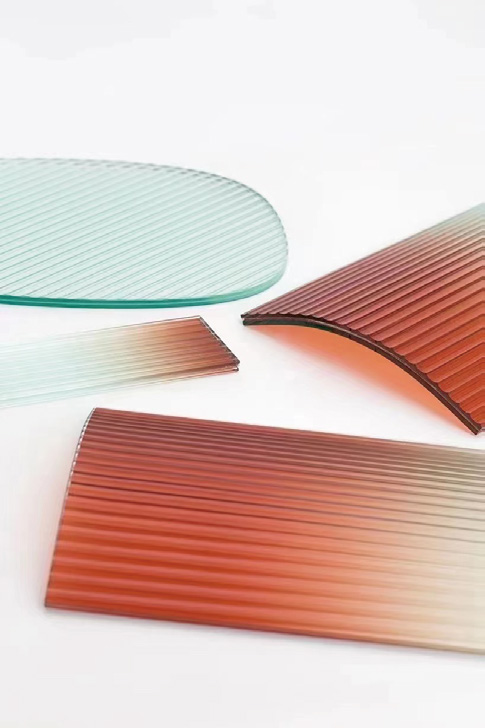

Sometimes there will be sharp angles or sharp edges after electro-engraving processing and such finished products are sometimes unsafe. After hot-melting, these sharp edges and corners can be burnt round and not too sharp, and at the same time, the engraved lines can be burned more translucent, and the overall appearance is crystal clear.

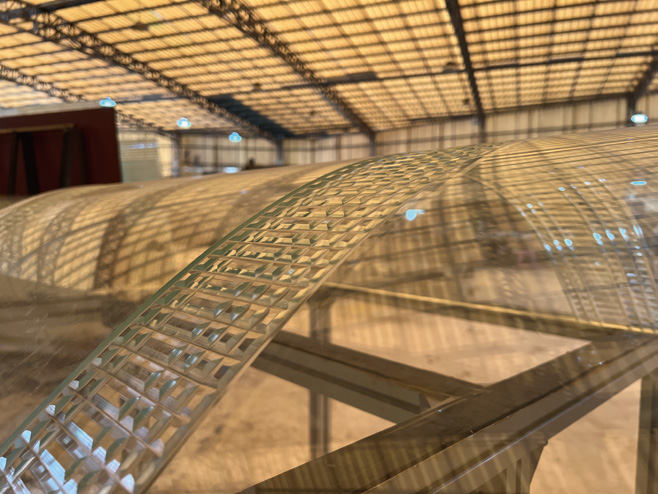

Can be made into a curved surface

The electro-engraved glass is made into a curved shape by overheating, and the application range is more comprehensive.

Can be tempered

Due to the flatness of the changed glass itself, the electro-engraved glass will be easily broken if the board surface is large, and there is safety and security. The strength of glass can be improved by tempering treatment, so as to reach the standard of tempered glass.

Reach the application standard of outdoor curtain wall

The strength of the glass can be improved by tempering, so as to meet the standard of tempered glass, and then the safety can be increased by laminating. The laminating treatment can prevent the glass fragments from falling and causing safety hazards in the event of a burst. Make it block 99% of ultraviolet rays, prevent ultraviolet rays from causing damage to the human body, and cause aging to indoor items.

Perfectly solve the problem of tempered glass flatness

Since the texture in tempered glass cannot be heated and cooled to achieve uniformity, the extreme flatness of the glass is affected. Through the study of process parameters, the horizontal tempering process can be controlled according to the national standard range of flat glass